Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

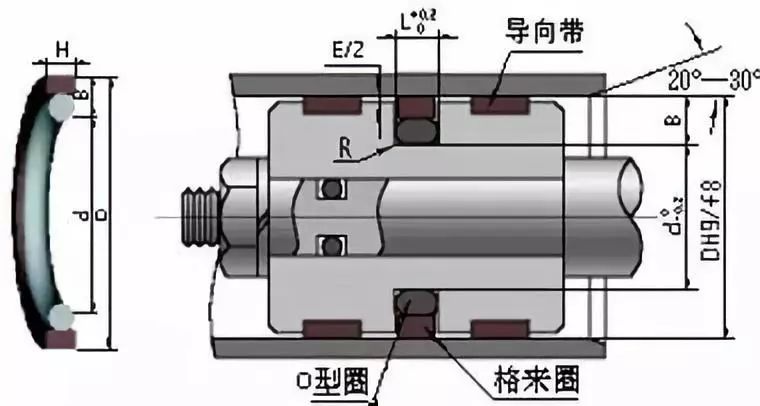

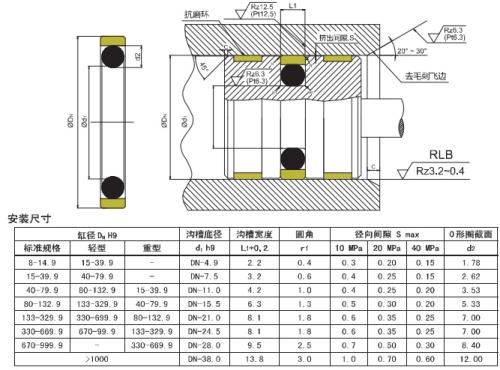

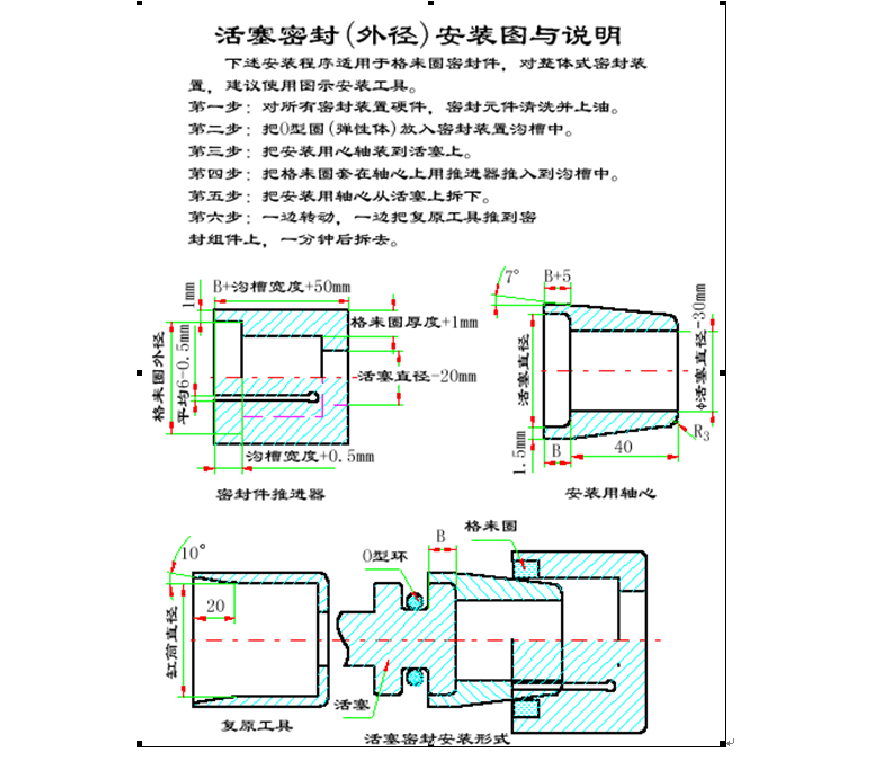

Due to the high elasticity of the O-ring, the installation is relatively easy; while the wear-resistant ring has poor elasticity, if it is directly installed, the steps and grooves of the piston will easily scratch the sealing surface and affect the sealing effect. In order to ensure that the wear ring is not damaged during installation, certain installation measures should be taken. The wear-resistant ring is mainly made of filled polytetrafluoroethylene (PTFE) material, which has the characteristics of corrosion resistance and a large thermal expansion coefficient. Therefore, it is soaked in oil at 100 ° C for 20 minutes before installation to gradually soften it. Then install it into the groove of the piston with the tool shown in Figure 2.

The tooling consists of a positioning sleeve and an expansion sleeve. The head of the locating sleeve has a 5o chamfer to guide the O-ring and wear ring into the groove on the end of the piston. The expansion sleeve is made of 65 Mn steel with better elasticity after heat treatment, and is processed into a uniform and symmetrical 8-lobed structure. It should be noted that when processing the small holes at the bottom of each lobe, the indexing should be uniform. When milling each lobe, the saw edge should be aligned with the center of the small hole to ensure that each lobe of the expansion sleeve can be opened evenly. At the same time, all parts should be chamfered (smoothly) to avoid damage to the sealing ring.

Each type of sealing ring should have a set of corresponding tooling to ensure its assembly requirements. After the installation is completed, the sealing ring is not allowed to be wrinkled, twisted, scratched or reversely installed.

The picture shows the cylinder of the hydraulic cylinder. The threaded holes on the cylinder are usually arranged after the welding process, so that burrs are inevitably generated at the junction between the outlet of the threaded hole and the inner wall of the cylinder. In order to remove burrs, special tools must be designed and manufactured to process them to achieve the purpose of smooth transition. Structure of special tool. When using, insert the shank from the threaded hole first, then install the cutter head on the shank from the side, and rotate the shank to remove the burrs and process a smooth and complete surface.

The picture shows the cylinder of the hydraulic cylinder. The threaded holes on the cylinder are usually arranged after the welding process, so that burrs are inevitably generated at the junction between the outlet of the threaded hole and the inner wall of the cylinder. In order to remove burrs, special tools must be designed and manufactured to process them to achieve the purpose of smooth transition. Structure of special tool. When using, insert the shank from the threaded hole first, then install the cutter head on the shank from the side, and rotate the shank to remove the burrs and process a smooth and complete surface.

Guohao seal ring - a solution provider for personalized solutions to "Oil Seals in various scenarios", more than 20 years of experience in seal material research and development, excellent seal design capabilities and experience in seal integration solutions, welcome to communicate.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.